Physicists have developed metamaterials for automotive shock absorbers

Time : 2021/5/29 16:09:38

Metamaterials are non natural substances and cannot be made by chemical reactions, but are made of geometric design in physical laboratory. Physicists can give metamaterials special and unimaginable properties. With the increasing popularity of this material, physicists have developed a set of toolbox to produce materials with a variety of given characteristics at the same time.

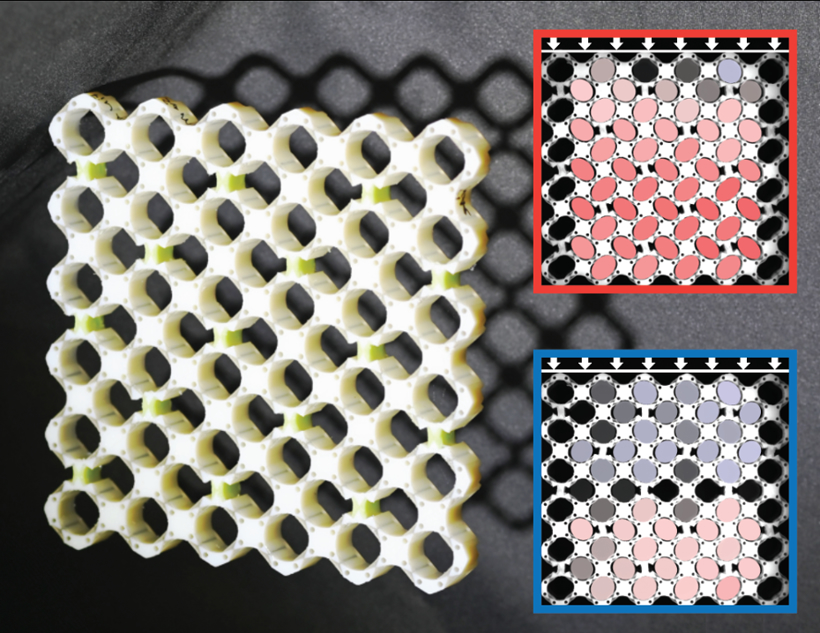

(photo source: University of Amsterdam)

The study was led by physicists Aleksi bossart, David Dykstra, job van der Laan and cornentin Coulais of the University of Amsterdam. Using the toolbox, these physicists create a material that can change its behavior when compressed quickly or slowly. These new materials can be used in automobile shock absorbers, earthquake resistant building materials or pressure valves with adjustable flow.

Super material is an engineering material with special properties due to its geometry rather than chemical composition. Its complexity depends on design rather than construction. Once the correct geometry is known, the 3D printer can make the material. Over the past few years, physicists have become more and more proficient in designing metamaterials with interesting properties. For example, a very light, very hard material, or a material with strange mechanical properties, which can shrink to the side when compressed, or even act as a programmable deformer, while the ordinary material can only be expanded,.

Although it's difficult to operate, the idea looks simple: if you need a material with specific properties, you'll find physicists to design it. But what if two special properties of materials are required? What if you need to switch between the two properties as appropriate?

These are typical problems people will encounter when they are looking for seismic materials. If the earthquake shock and the small vibration of the building in daily life, this kind of material needs to make different response. Considering such applications, bossart, Dykstra, van der Laan and Coulais began to design a material that has multiple functions in a single structure, not only one function.

So they try to create super materials that shrink or expand at the side at the rate of compression. The above figure shows an example of this material: the key to the function of the material is the pattern of its hole. When pressure is applied, all holes deform together, but when pressure is applied slowly, it will be different from that of the rapid application of pressure.